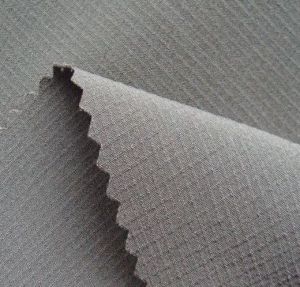

Ripstop is a versatile material it comes in a wide range of weights and colours.

© 2023 Sbf Interiors. All Rights Reserved.

Development by Starling Technologies

Ripstop is a versatile material it comes in a wide range of weights and colours.